Construction of metal silos: certified excellence

EN 1090-1:2009 + A12011 certification

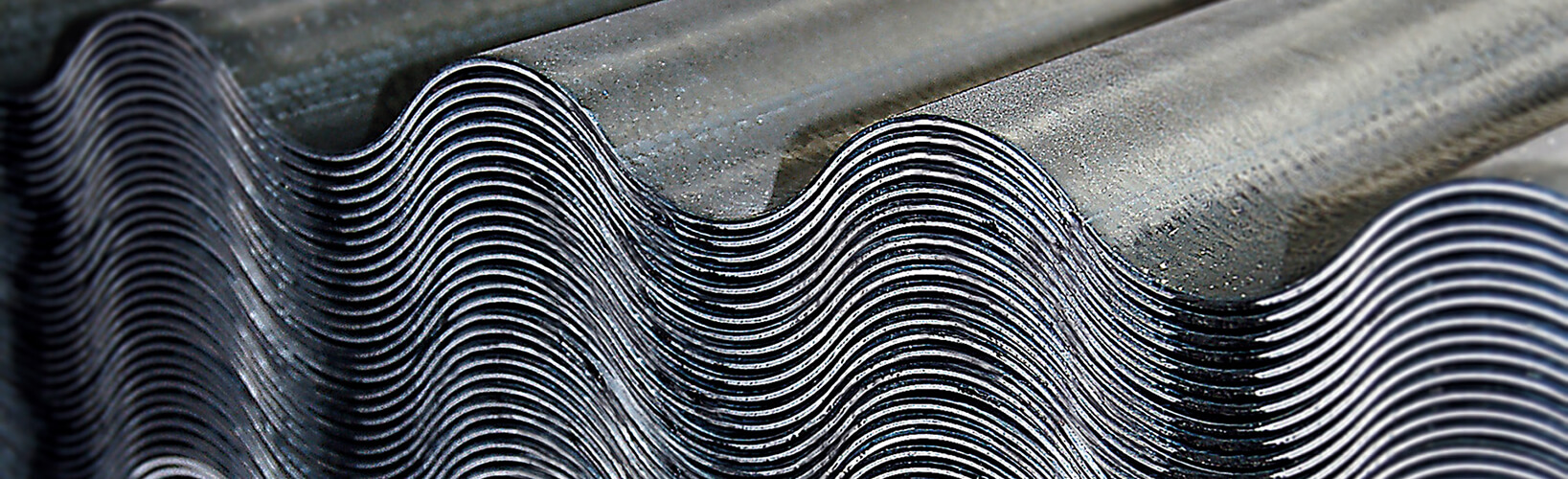

In 2014, Mulmix obtained the EN 1090-1:2009 + A12011 certification, which sets the basic standards for the construction of components and elements in aluminum or steel for the construction of metal silos for cereal storage, supporting structures, and metal carpentry. Each manufactured item has an identifying code stamped on it, allowing the material used to be traced from the steel mill cast to the finished product. The material certificates and sample tests are archived in the Mulmix management system and made available to the purchaser or the competent authorities. The machines, structures, and connecting elements are subject to anti-corrosion treatments such as galvanizing or epoxy powder coating to ensure longer durability of the plants while respecting the environment.

UNI EN ISO 9001:2015 certification

Mulmix obtained the UNI EN ISO 9001:2015 certification in 2016, after achieving the previous versions in 2004 and 2008. This choice demonstrates the company's commitment to constantly monitoring and improving its performance in business processes. Maintaining certification is a priority for Mulmix to ensure that the solutions provided meet not only the requirements of the standard but also the implicit and explicit expectations of its customers. All employees are engaged and involved in the management and maintenance of the Quality System in the company to promote competence and professionalism towards customers with "best practices".

ISO 14001 certification

In 2022, Mulmix obtained the ISO 14001 certification, demonstrating its attention to environmental sustainability policies and its commitment to the planet.Within its facilities, Mulmix has promoted a series of strategic plans such as:

- raising awareness among resources to reduce water and energy consumption

- increasing the waste management mode to recover rather than dispose of it

- encouraging recovery and reuse activities in operational activities

Moreover, Mulmix avoids the use of hazardous substances and the production of emissions into the atmosphere that require authorizations or cause significant noise impacts, thus protecting the health of its workers and the environment. The company controls the risk of introduction and/or spread of quarantine harmful organisms associated with raw wood packaging materials by using FAO ISPM 15 certified wood packaging. Additionally, it uses qualified, regenerated, and certified materials such as polyethylene and employs increasingly efficient and long-lasting corrosion protection treatments that ensure a longer useful life for the silos.With this certification, Mulmix confirms itself as an environmentally responsible supplier in the national and international market.

M.O.C.A Compliance Declaration

Mulmix has reached a new important milestone in the construction of metal silos: the Compliance Certification for M.O.C.A. (Materials and Objects in Contact with Food). The M.O.C.A. guarantees compliance with specific mandatory hygiene requirements, and their control ensures that there is no transfer of components or contamination of food products with which they come into contact.Mulmix has activated an internal product traceability process for many years, and thanks to this internal control and identification system, it is also possible to guarantee complete traceability for M.O.C.A.To obtain this certification, several tests, checks, analyses, and technical tests of the materials used were carried out, eliminating and/or replacing those deemed unsuitable. A good manufacturing practices system was established according to legal requirements and a Quality Assurance and Control System capable of guaranteeing a level of contaminant element release to the product within the maximum limits set by national and European laws, ensuring that there is no danger to human health.Obtaining M.O.C.A. compliance was a long and demanding process that allows the company to offer its customers safe and certified products made in compliance with EC Regulation 1935 of the European Parliament and of the Council of 27 October 2004. The release tests were carried out according to the European guide Metals and Alloys used in food contact Materials and Articles (EDQM/COE) - ICP - OES/ICP - MS.